Photos & Video

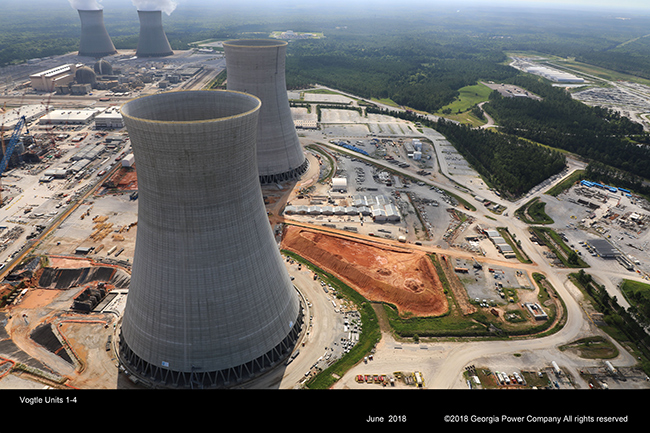

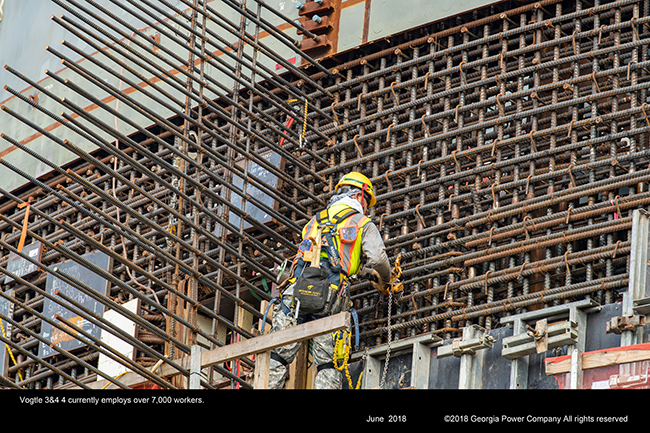

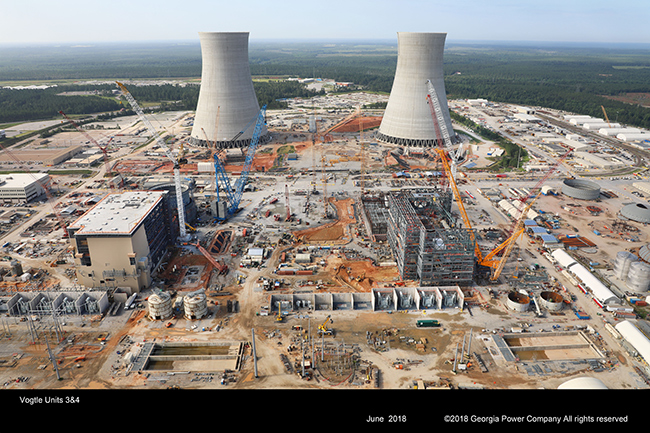

The new Vogtle units are an essential part of Georgia Power's commitment to deliver safe, clean, reliable and affordable energy for customers and play a significant role in supporting Southern Company's goal of net-zero carbon emissions by 2050. Once operating, each of the two new units at Plant Vogtle can generate enough electricity to power an estimated 500,000 homes and businesses. A diverse fuel mix, including nuclear, is also essential to maintaining a reliable and affordable energy infrastructure that attracts new investment, supports economic growth and creates jobs.

Milestones

Vogtle 3 and 4 Milestones 2020

December

Georgia Power received the first nuclear fuel shipment for Vogtle Unit 3, representing the first nuclear fuel shipment for this newly-designed AP1000 reactor in the U.S. In order to receive nuclear fuel, construction of specific areas of Unit 3 had to be completed and inspected, ensuring critical infrastructure, such as the fuel vault and spent fuel pool, meet construction quality and design requirements. With site construction turning over the fuel handling area of Vogtle Unit 3 to operations, the Vogtle 3 & 4 site implemented specific and comprehensive policies, procedures and security measures to safely receive, handle and store the nuclear fuel.

The two-million-pound roof of the Vogtle Unit 4 shield was set into place. The Unit 4 shield building roof measures 135 feet in diameter, 37 feet tall and weighs more than two fully-loaded jumbo jets. The shield building is a unique feature of the AP1000 reactor design for Vogtle 3 & 4, providing an additional layer of safety around the containment vessel and nuclear reactor to protect the structure from any potential impacts.

Georgia Power announced the completion of the pre-operational condenser vacuum test of the Vogtle Unit 3 turbine system. The test was conducted with the main turbine on turning gear and by operating supporting systems to establish the condenser vacuum, which is necessary to demonstrate the steam supply and water-cooling systems operate together and are ready to support hot functional testing and initial fuel load in the reactor. The condenser is part of the plant's turbine system, separate from the nuclear reactor, that liquifies steam to be reused after its passes through the high- and low-pressure turbines to power a generator and produce electricity. The condenser vacuum test required multiple systems, including circulating water, condensate, auxiliary steam and condenser air removal, to be operated in an integrated manner after having been successfully tested individually.

October

Georgia Power announced the completion of cold hydro testing for Vogtle Unit 3 at the company's nuclear expansion project near Waynesboro, Ga. The completion of the cold hydro testing milestone prepares the site for the last major test remaining for Unit 3, hot functional testing, ahead of initial fuel load. Cold hydro testing of Unit 3 confirmed the reactor's coolant system functions as designed and verified the welds, joints, pipes and other components of the coolant system and associated high-pressure systems do not leak when under pressure. As part of the testing, the reactor coolant system was filled with water and pressurized above-normal operating conditions, then lowered to normal design pressure while comprehensive inspections were conducted to verify the systems meet design standards.

July

A major testing milestone on the Vogtle Unit 3 containment vessel's structural integrity and safety functions has been completed at Georgia Power's nuclear expansion project near Waynesboro, Georgia. The structural integrity test and integrated leak rate test were completed in succession and demonstrated the containment vessel meets construction quality and design requirements. The containment vessel serves as a barrier to protect the public and surrounding communities by containing material produced inside the reactor vessel in the unlikely event of an emergency.

Closed Vessel Testing has been completed for Vogtle Unit, marking continued progress with critical testing. The completion of this milestone prepares Unit 3 for cold hydro testing, which is required ahead of initial fuel load. Closed Vessel Testing verifies the pipes and valves in the Unit 3 reactor coolant system were installed as designed and helps ensure safety systems function properly. To carry out Closed Vessel Testing on the plant's passive safety systems, workers installed the reactor vessel head as well as the lower and upper reactor internals and flow restrictors. These will be used during hot functional testing to mimic flow through the reactor core.

May

Open Vessel Testing, a major systems testing milestone, is complete for Unit 3 at Georgia Power's Vogtle 3 & 4 nuclear expansion project near Waynesboro, Georgia, marking one of the most significant accomplishments in the project to date. Open Vessel Testing has successfully demonstrated how water flows from the key safety systems into the reactor vessel ensuring the paths are not blocked or constricted. It also prepares Unit 3 for cold hydro testing and hot functional testing – both critical tests required ahead of initial fuel load. The milestone has confirmed that the pumps, motors, valves, pipes and other components of the systems function as designed.

The Integrated Head Package (IHP) for Vogtle Unit 3 has been set into place atop the reactor vessel at Georgia Power's nuclear expansion project near Waynesboro, Georgia, marking another significant milestone in the construction of the nation's first new nuclear units in more than 30 years. Standing 48 feet tall, weighing 475,000 pounds and containing more than three miles of electrical cables, the IHP is an integral component that will eventually be used by highly-trained nuclear operators to monitor and control the nuclear reaction that will occur inside the Unit 3 reactor vessel.

The final module for Georgia Power's Vogtle Unit 3, a massive water tank, has been placed atop the containment vessel and shield building roof at the company's Vogtle 3 & 4 nuclear expansion project near Waynesboro, Georgia. The installation represents the final module placement for Unit 3, marking another significant milestone for the project. The large module, known as CB-20, is a major part of the AP1000 reactor's advanced passive safety system. Standing 35 feet tall and weighing more than 720,000 pounds, the large component will hold approximately 750,000 gallons of water ready to flow down in the unlikely event of an emergency to help cool the reactor. The water can also be directed into the used fuel pool, while the tank itself can be refilled from water stored elsewhere on site.

March

Georgia Power ordered the first nuclear fuel load for Vogtle Unit 4, completing the initial fuel order needed to operate the first newly-designed reactors in the U.S. in 30 years. Consisting of 157 fuel assemblies with each measuring 14 feet tall, the fuel will eventually be loaded into the reactor vessels to support startup once the reactors begin operating. After the initial fueling, approximately one third of the total fuel assemblies will be replaced during each refueling outage after the units begin operating, similar to the process used at existing Vogtle units 1&2.

The final major lifts inside the containment vessels for Vogtle 3 & 4 were complete following the placement of the Unit 4 containment vessel top head in March. The containment vessel is a high-integrity steel structure that houses critical plant components. The top head is 130 feet in diameter, 37 feet tall, and weighs nearly 1.5 million pounds, more than two fully-loaded jumbo jets. It's comprised of 58 large plates, welded together, each more than an inch and a half thick.

February

Workers at Georgia Power's Vogtle 3 & 4 project completed the final concrete placement inside the Unit 3 containment vessel, which houses the unit's reactor. Completing this milestone is an important step that allows for the installation of machinery that will be used to load fuel into the unit.

Vogtle 3 and 4 Milestones 2019

August

Integrated Flush for Unit 3 officially began Aug. 5, as water was pushed through the Spent Fuel Pool Cooling system for the first time. The Integrated Flush process involves cleaning and testing of system piping and components that feed into the reactor vessel or reactor coolant loops by flushing them with water. The start of Integrated Flush is a major step on the path to operations for Vogtle 3&4, helping to ensure that Unit 3 will start up in a safe manner.

July

A group of components known as “lower internals” were inserted in the Unit 3 reactor vessel for the first time. This step is part of a customization process to verify the exact location and fit-up of these complex components. The achievement is a key predecessor for open vessel testing, which is scheduled to begin at the end of November.

June

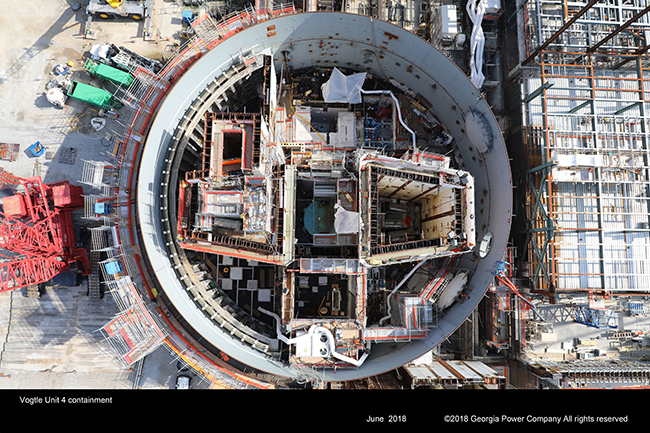

On June 28, another key milestone was achieved with the placement of the middle containment vessel ring for Unit 4. The containment ring is part of the structure that houses the reactor vessel. Weighing more than a jumbo jet, the 2.4 million-pound, 51-foot tall containment vessel ring consists of dozens of individual steel plates and was fabricated on site.

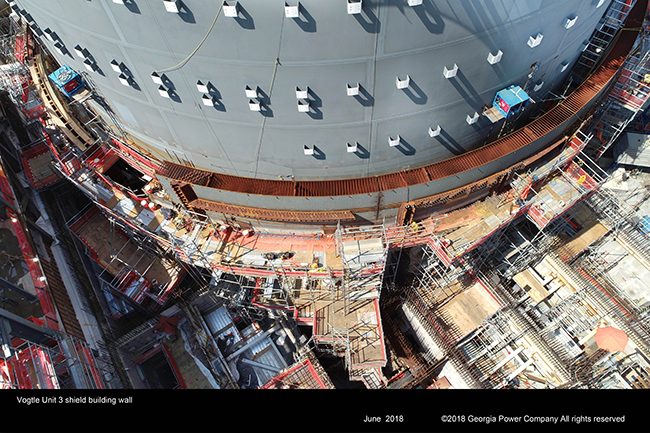

Also in June, a placement of more than 930 cubic yards of concrete was completed inside the Unit 3 shield building. The Unit 3 shield building is now more than 80 percent complete as the construction team moves closer to completion of the protective barrier that surrounds the Unit 3 containment vessel.

May

The Vogtle 3&4 team energized the reserve auxiliary transformers for the first time. This key step was followed by energization of the 6.9kV switchgear and load centers. These steps completed Initial Energization, Vogtle 3&4’s first milestone of the second quarter.

Also, the second milestone of the second quarter was achieved as three concrete placements making up the maintenance deck were completed in Unit 4 containment.

March

The top of the containment vessel for Unit 3 was lifted into place during March, marking one of the most important milestones to date at the Vogtle expansion project. The placement signifies that all modules and large components have been placed inside the unit.

Also in March, Georgia Power and the Department of Energy (DOE) announced the closing of approximately $1.67 billion in additional DOE loan guarantees for the new Vogtle units. Energy Secretary Rick Perry announced the loan closure while visiting the Vogtle 3&4 site. Georgia Power had previously secured loan guarantees of $3.46 billion for construction of the new units.

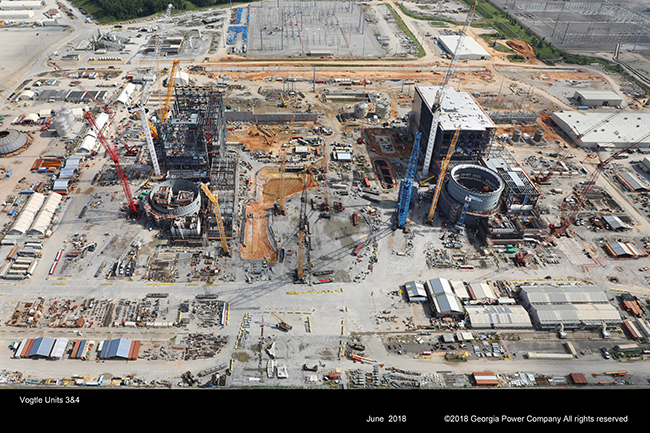

Vogtle 3 and 4 Milestones 2018

December

Another milestone was achieved with the placement of the third and final ring that comprises the Unit 3 containment vessel. Weighing almost 2 million pounds, standing approximately 38 feet high and with a diameter of 130 feet, the ring is the fourth of five sections that make up the containment vessel, a high-integrity steel structure that houses critical plant components.

November

The first two sets of double-decker shield building panels were placed around the outer wall of the Unit 3 containment vessel. The panels provide structural support to the containment cooling water supply and protect the containment vessel, which houses the reactor vessel and associated equipment. A total of four six-panel sections were placed, with each one measuring 20 feet tall and 114 feet wide and weighing from 180,000 to 300,000 pounds.

September

In September, the Vogtle 3&4 team placed both accummulators inside Unit 4 containment. Accumulators make up part of the AP1000 passive core cooling system. Weighing 185,000 pounds each, they are spherical tanks of borated water inside the containment vessel. Two accummulators are required for each of the new Vogtle units and both had already been placed in Unit 3. Lessons learned from Unit 3 resulted in schedule efficiencies and improved overall performance for the Unit 4 accumulator placements.

August

The first steam generator was successfully placed in Vogtle Unit 4 on Aug. 24, completing the final major milestone for the third quarter. Weighing 1.3 million pounds and measuring more than 62 feet long, the steam generator is a heat exchanger used to convert water into steam using the heat produced in a nuclear reactor core.

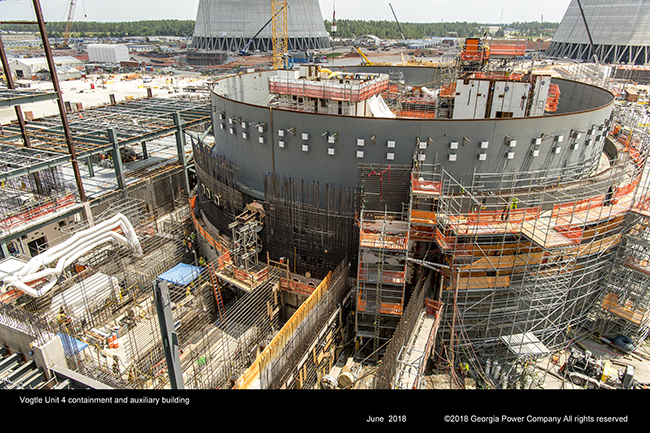

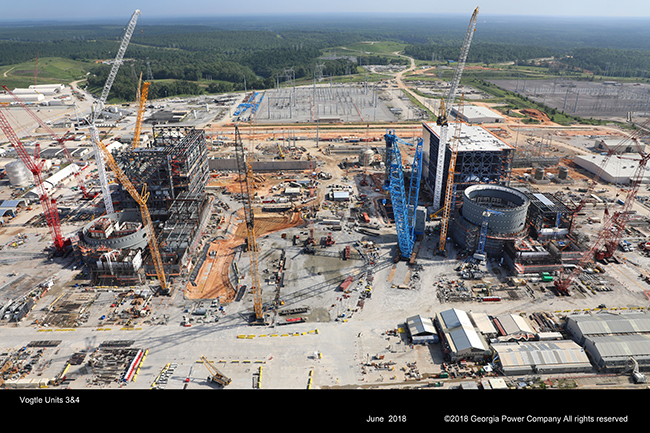

June

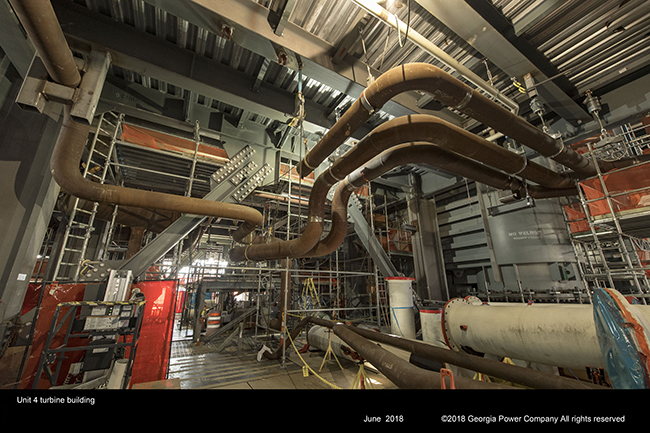

A top Vogtle 3&4 milestone for 2018 was achieved in June with the setting of the main generator stator assembly in the Unit 4 turbine building. The milestone was achieved months ahead of schedule, another indicator of positive momentum on the site.

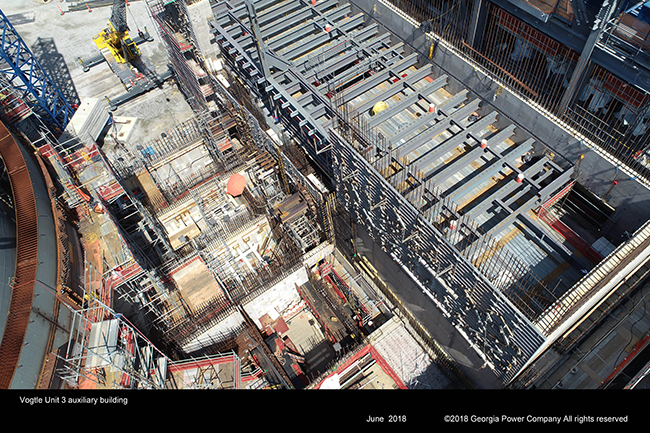

Also in June, the Vogtle 3&4 team completed the final reinforced concrete placement for a portion of the Unit 3 shield building, one of the top milestones for 2018.

May

Vogtle 3&4 construction teams completed the placement of four main step-up transformers inside the Unit 4 transformer bays. Weighing 420,000 pounds each, the transformers will increase the voltage produced by the turbine generators from 26,000 volts to 500,000 volts before the energy flows to the power grid to serve hundreds of thousands of customers.

April

The Vogtle 3&4 team reached another milestone with the recent placement of the passive residual heat removal (PRHR) heat exchanger inside the Unit 3 containment vessel. The PRHR heat exchanger is a key feature of the AP1000 reactor’s passive core cooling system, which is part of the larger AP1000 passive safety system.

March

A major step in the Vogtle 3&4 construction process was achieved March 28 with the safe placement of the Unit 4 reactor vessel inside the nuclear island. Standing 35 feet tall, the reactor vessel functions as a heat source from the nuclear fission process to produce steam that will generate electricity.

January

Another key milestone was achieved in January with the placement of the Unit 3 pressurizer, which will provide pressure control inside the reactor coolant system once the unit begins operating. Due to improved planning and coordination, the pressurizer was set ahead of schedule.

Vogtle 3 and 4 Milestones 2017

December

Georgia Power and the other Vogtle co-owners, Oglethorpe Power, MEAG Power and Dalton Utilities, received a total of $3.68 billion in parent guarantee payments from Toshiba, the full amount owed by the parent company of former primary Vogtle contractor Westinghouse.

Georgia Power received unanimous approval from the Georgia Public Service Commission to complete Vogtle units 3 and 4.

November

The last of the "Big 6" modules, the 52-ton CA02 module for Unit 4, is placed.

October

In an effort to raise money for the Family YMCA being built in Burke County, Ga., the Plant Vogtle employees held the fifth annual Sporting Clays Tournament and Golf Tournament. raised more than $144,000. Since the event started in 2013, more than $500,000 has been raised in support of the local community.

Major milestones achieved at the construction site included a critical concrete 'super placement,' lasting 71 hours, for Unit 3 and the lift of the 237-ton CA03 module for Unit 4.

September

Georgia Power announced a new agreement with the U.S. Department of Energy (DOE) for a conditional commitment of approximately $1.67 billion in additional loan guarantees. With a total of more than $5 billion in anticipated DOE loan guarantees, Georgia Power expects to be able to provide more than $500 million in present-value benefits to its customers.

Major milestones at the construction site during September included the placement of the deaerator for Unit 4 and the Unit 3 steam generator.

August

Second accumulator tank placed inside Unit 3 containment vessel

On Aug. 19, the second accumulator tank was successfully placed inside the Unit 3 containment vessel. Each AP1000 unit requires two accumulator tanks – the first Unit 3 accumulator tank was placed late last month.

Each tank weighs 85,000 pounds and is approximately 17 feet long, 16 feet wide and 17 feet tall. Part of the AP1000 passive core cooling system, accumulators are spherical tanks of borated water inside the containment vessel. In the event of a loss of reactor coolant, the tanks are designed to provide a high rate of coolant flow into the reactor for several minutes.

August

Construction progress continues with placement of Unit 4 CA01 Pressurizer Bay

The CA01 Pressurizer Bay was successfully placed in the Unit 4 containment vessel on Aug. 18. The component is 60 feet tall, 40 feet wide and weighs 240,000 pounds.

The achievement follows last week’s successful placement of the Unit 3 steam generator and continues positive momentum during the past few weeks. For example, the KQ22 and KQ23 modules, as well as both accumulator tanks, were recently placed in the Unit 3 containment vessel.

August

Steam generator successfully placed into Unit 3 containment

The first steam generator was successfully placed into Unit 3 containment on Aug. 15. There are two steam generators per unit in the AP1000 design.

The 1.4 million pound, 78-feet long component was the first lift with the new Lampson crane, which will be used for major lifts going forward.

Steam generators are heat exchangers used to convert water into steam from heat produced in the nuclear reactor core. Each generator is a vertical-shell U-tube evaporator with integral moisture separating equipment. Simply put, high temperature water from the reactor coolant system flows through more than 10,000 tiny tubes in the steam generator and turns water into high pressure steam to spin the turbines.

July

Accumulator tank A successfully placed inside Unit 3 containment

The first accumulator tank was successfully placed inside the Unit 3 containment vessel on July 26. Each AP1000 unit requires two accumulator tanks.

Part of the AP1000 passive core cooling system, accumulators are spherical tanks of borated water inside the containment vessel. In the event of a loss of reactor coolant, the tanks are designed to provide a high rate of coolant flow into the reactor for several minutes.

Each tank weighs 85,000 pounds and is approximately 17 feet long, 16 feet wide and 17 feet tall. The tanks are manufactured in Italy by Mangiarotti, a manufacturer of components for nuclear plants and oil and gas drilling.

July

Georgia Power finalizes new service agreement for Vogtle nuclear expansion

Georgia Power has finalized a new service agreement with Westinghouse for the Vogtle nuclear expansion – the first new nuclear units to be built in the United States in more than 30 years. Previously, Westinghouse, the developer of the AP1000 nuclear technology being used by the new units, served as the primary contractor with oversight and responsibility for all construction activities.

Under the new service agreement, approved by the U.S. Department of Energy on July 27, Southern Nuclear (the Southern Company subsidiary which operates the existing units at Plant Vogtle) will oversee construction activities at the site.

The scope of the service agreement includes engineering, procurement and licensing support from Westinghouse, as well as access to Westinghouse intellectual property needed for the project. Under the new structure, hundreds of Georgia Power and Southern Nuclear employees, many who are already aligned with the project, will assume clearly defined project management roles.

Georgia Power also continues work with the project’s Co-owners (Oglethorpe Power, MEAG Power and Dalton Utilities) to complete a full-scale schedule and cost-to-complete analysis of the project. Once complete, Georgia Power will work with the Georgia Public Service Commission to determine the best path forward for customers.

Following the Westinghouse bankruptcy filing on March 29, construction momentum has continued uninterrupted.

February

Placement of Unit 4 Shield Building Panels

Another key construction milestone was achieved at Vogtle 3 and 4 with the placement of six panels at the Unit 4 Shield Building. Following this first panel placement – referred to as the “Course 1” placement – the panels were then filled with 410 cubic yards of concrete.

The Unit 4 Shield Building is made of steel and concrete in what is known as a steel composite design that is about 150 feet high and about three feet thick.

A typical panel is 37 feet long, 10 feet high, three feet thick and weighs approximately 30,600 pounds. Comprised of more than 160 individual steel panels, the shield building provides structural support to the containment cooling water supply and protects the containment vessel, which houses the reactor vessel and associated equipment.

Vogtle 3 and 4 Milestones 2016 - 2013

2016

February - The safe placement of eight new shield building panels for Unit 3. The shield building will encapsulate the containment vessel and is comprised of more than 160 individual steel panels.

May - The last of the "Big 6" modules - CA02 and CA03 are placed. The modules, weighing 52 tons and 237 tons, respectively, are critical components and part of the In-Containment Refueling Water Storage Tank.

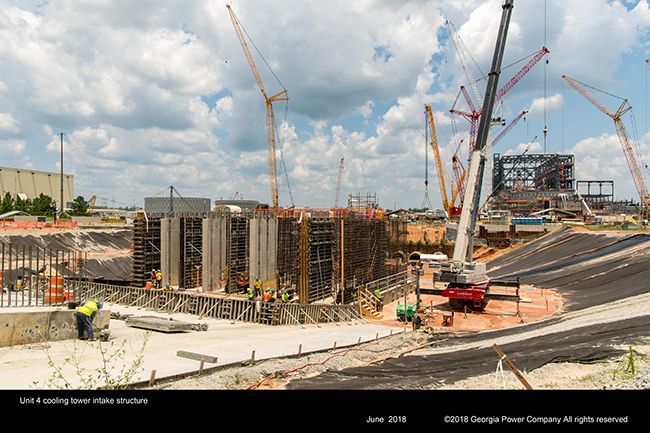

June - The safe placement of the CA05 module jumpstarted activities in June as the 90-ton module is a key component that provides critical structural support for the containment building. Crews also completed vertical construction of the 600-foot Unit 4 cooling tower.

August - One of the heaviest lifts of the project took place when the 2 million-pound or 1,000 ton, CA20 module was placed.

October - The first class of Vogtle 3 & 4 nuclear operators passed the Nuclear Regulatory Commission licensing exam, ensuring that licensed, qualified operators are in place prior to nuclear fuel loading and the plant start up.

November - With the receipt of the final National Pollutant Discharge Elimination System (NPDES), or water discharge, permit by the Georgia Environmental Protection Division, all major permits are now in place for the new units.

November /December - The nuclear construction team concluded the year on a high note with the placement of the second containment vessel ring for Unit 3. Other major lifts included the setting of both the 612,000-pound Unit 3 reactor vessel and 2-million pound Unit 4 CA01 module.

December - The Georgia Public Service Commission (PSC) unanimously approved an agreement between Georgia PSC staff and Georgia Power, confirming the prudent investment of $5.68 billion by the company in the Vogtle nuclear expansion. Under the agreement, all capital costs incurred by the company up to $5.68 billion, including $3.3 billion invested through the end of 2015 and the $350 million settlement agreement with the project's contractors will be presumed to be reasonable and prudent. The agreement fairly balances the company's contribution with customer benefits and is expected to deliver approximately $325 million in savings to customers during the construction period, while keeping the project's overall projected rate impact to customers at 6 to 8 percent.

2015

June - The second steam generator for Unit 3, steam generator A, arrived safely to the Vogtle construction site on June 7. Like its counterpart that was delivered in March, this massive component was fabricated in South Korea, shipped to the Port of Savannah and then delivered by railcar to the Vogtle site. Units 3 and 4 will each have two steam generators, which are heat exchangers used to convert water into steam from heat produced in the nuclear reactor core. Both of the Unit 4 steam generators are being prepared for delivery in the coming months.

March - The Unit 3 steam generator B arrived via rail at the Plant Vogtle construction site March 23, completing its journey from South Korea. The component, weighing 1.3 million pounds and measuring 82 feet in length, is the first of four steam generators that will arrive in the coming months. After arriving in the port of Savannah, the steam generator was offloaded onto a specially designed railcar for the 118-mile trip to the Vogtle site. Officials said it was the heaviest lift ever for the Savannah port.

2014

December - The Vogtle Unit 3 cooling tower reached its final height of 601 feet.

October - The project team successfully placed the 180,000-pound CA05 module into the Unit 3 nuclear island. The CA05 structural module is housed within the Unit 3 containment building and is comprised of reinforced steel plates that will be filled with concrete to provide structural support for the containment building. In addition to providing structural support, the protective walls of CA05 will also separate various rooms in containment.

October - The 1.9 million-pound lower ring was set on top of the Unit 3 containment vessel bottom head. Measuring more than 50 feet tall, the lower ring was one of the largest lifts of the project.

May - The Unit 4 containment vessel bottom head (CVBH) was successfully placed into that unit's nuclear island. The CVBH weighs more than 1.8 million pounds, or 900 tons, and is nearly 38 feet tall and 130 feet wide. The component consists of dozens of individual steel plates and was fabricated on site by CB&I, the project's contractor.

March - The Vogtle 3 and 4 project team successfully placed the CA20 module into the Unit 3 nuclear island. Weighing more than 2.2 million pounds, or 1,100 tons, and towering more than five stories tall, the module is the heaviest "lift" of the project to date. With a footprint of approximately 67 feet long by 47 feet wide, the critical module will house various plant components, including the used fuel storage area.

February - The 460-ton CR10 module, or cradle, is lifted into the Unit 4 nuclear island using the heavy lift derrick.

February - Approximately 5,300 cubic yards of self-consolidating concrete is placed under the Unit 3 containment vessel bottom head (CVBH) in a continuous pour that lasted 35 hours. The concrete will provide support for the CVBH and be part of the foundation for the shield building.

2013

December - The CA04 module, also known as the reactor vessel cavity, was lifted into the Unit 3 nuclear island.

November - The National Nuclear Accrediting Board (NNAB) awarded initial accreditation for the Vogtle 3 and 4 Maintenance and Technical Training Programs.

November - First nuclear concrete placed for Unit 4 basemat.

September - The 717-ton condenser A lower shell is placed into the Vogtle Unit 3 turbine island.

August - Vogtle Unit 4 deaerator arrives on site.

June - Containment vessel bottom head placed into Unit 3 nuclear island.

April - CR10 cradle placed in Unit 3 nuclear island.

March - First nuclear concrete placed for Unit 3 basemat.

February - Vogtle Unit 3 deaerator arrives on site.

Vogtle 3 and 4 Milestones 2012 - 2005

2012

October - Vogtle 3 and 4 project surpasses 10 million work hours at the site.

August - Load test for the Heavy Lift Derrick is completed.

February - Nuclear Regulatory Commission issues Construction and Operating Licenses for Vogtle units 3 and 4.

February - The condenser for Unit 3 arrives on-site in the first rail delivery of components for the Vogtle 3 and 4 project.

2011

December - The Nuclear Regulatory Commission certified Westinghouse Electric Co.'s AP1000 reactor design.

August - Southern Nuclear received the Final Safety Evaluation Report from the Nuclear Regulatory Commission's technical staff for the Combined Construction and Operating License for Vogtle units 3 and 4.

August - Training classes began at a new state-of-the-art facility built for initial and continuing training of Vogtle units 3 and 4 employees.

August - The Nuclear Regulatory Commission issued the Final Safety Evaluation Report for Westinghouse Electric Company's AP1000 reactor design.

July - The first AP1000 component, a floor section of a very large structural module that ultimately will become the plant's auxiliary building, was delivered by Shaw Modular Solutions to the Vogtle 3 and 4 site.

April - The mudmats for units 3 and 4 are poured.

March - The Nuclear Regulatory Commission completed its Final Supplemental Environmental Impact Statement (FSEIS) for a Limited Work Authorization (LWA) and the Combined Construction and Operating Licenses (COL) for the Vogtle units 3 and 4. The NRC, in its FSEIS, concluded that there are no environmental impacts that would preclude issuing the LWA and COLs for construction and operation of the proposed reactors at the site.

2010

June - Southern Company and the Department of Energy (DOE) announced that the company's Georgia Power subsidiary has reached an agreement with DOE to accept terms for a conditional commitment for loan guarantees for Vogtle units 3 and 4.

March - Safety-related construction began with the first placement of backfill soil into the area excavated for Unit 3.

February - President Obama and DOE Secretary Steven Chu announce the award of conditional loan guarantees for Vogtle Units 3 and 4. The DOE loan guarantees are expected to save Georgia Power's customers millions in interest costs annually over the expected life of any guaranteed borrowing.

2009

August - Excavation of the area where the new units are planned began at the plant site.

August - Plant Vogtle Units 3 and 4 received an ESP from the NRC. The Vogtle ESP is the first in the industry to reference a specific technology and to come with a Limited Work Authorization (LWA) which allows limited safety-related construction at the site prior to receiving the COL.

July - Southern Nuclear begins training Operations instructors for Vogtle Units 3 and 4.

June - Southern Nuclear cleared another hurdle in the licensing process for new units at Plant Vogtle when the Nuclear Regulatory Commission's Atomic Safety and Licensing Board issued its ruling on contentions related to the Early Site Permit (ESP) application. The ASLB ruled in favor of Southern Nuclear and the Nuclear Regulatory Commission staff in all cases.

May - Plant Vogtle Units 3 and 4 were named NuStart's reference plant for AP1000 technology.

April -- Georgia Gov. Sonny Perdue signed into law Senate Bill 31, which allows Georgia Power to recover financing costs during the construction of nuclear units while they're being built, plus reducing the plant's costs to customers.

April - Georgia Power provided the Westinghouse-Shaw consortium full notice to proceed on Plant Vogtle Units 3 and 4. Shaw and Westinghouse began mobilizing at the plant site and performing activities to support construction.

March - The NRC's ASLB held its hearings to review contentions on the Plant Vogtle ESP.

March - Georgia Power received certification from the Georgia Public Service Commission to build new units at the site.

2008

November - Southern Nuclear was notified that five petitioners filed a petition to intervene in the COL application that the company filed for new units at Plant Vogtle. The groups are Atlanta Women's Action for New Direction (WAND), Blue Ridge Environmental Defense League (BREDL), Center for a Sustainable Coast, Savannah Riverkeeper and Southern Alliance for Clean Energy (SACE).

May - Georgia Power submitted a nuclear self-build option to the Georgia Public Service Commission (PSC) to meet demand in the 2016-2017 timeframe. The company received no other bids in response to its 2016-2017 baseload capacity request for proposals. The Georgia PSC rules require market bids to be compared with self-build proposals, but no market bids were received.

April - Georgia Power entered into an Engineering, Procurement and Construction contract with the Westinghouse-Shaw consortium to construct two Westinghouse AP1000 units at the site. This agreement was signed on April 8, 2008.

March - Southern Nuclear filed a Combined Construction and Operating License (COL) application with the NRC for new units at the Vogtle site.

2007

March - The NRC's Atomic Safety and Licensing Board (ASLB) announced that it will allow a group of organizations to intervene in the ESP process for new units at Plant Vogtle. This announcement came following a pre-hearing in February where the ASLB reviewed information presented by the intervenors.

2006

December - A group of organizations filed a petition to intervene in the ESP for Plant Vogtle Units 3 and 4. The groups are Atlanta Women's Action for New Direction (WAND), Blue Ridge Environmental Defense League (BREDL), Center for a Sustainable Coast, Savannah Riverkeeper and Southern Alliance for Clean Energy (SACE).

August - Southern Nuclear filed an Early Site Permit (ESP) for new units at the Plant Vogtle site.

January - Southern Nuclear selects Westinghouse AP1000 technology for new units at the Plant Vogtle site.

2005

August - Southern Nuclear announced its intent to file an ESP or pre COL application in the summer of 2006.

August - Southern Nuclear announced, on behalf of the Plant Vogtle co-owners, that it had officially informed the NRC that it had selected the Plant Vogtle site to evaluate for possible new nuclear generation.

August - The Energy Policy Act of 2005 was signed into law.

July - Southern Nuclear notified the NRC of a potential site selection for its ESP application. That site was Plant Vogtle.

February - Southern Nuclear sent a notice of intent letter to the NRC stating its intent to submit an application for an Early Site Permit for a new nuclear plant. At that time, the company said that no site had been selected for new nuclear generation.